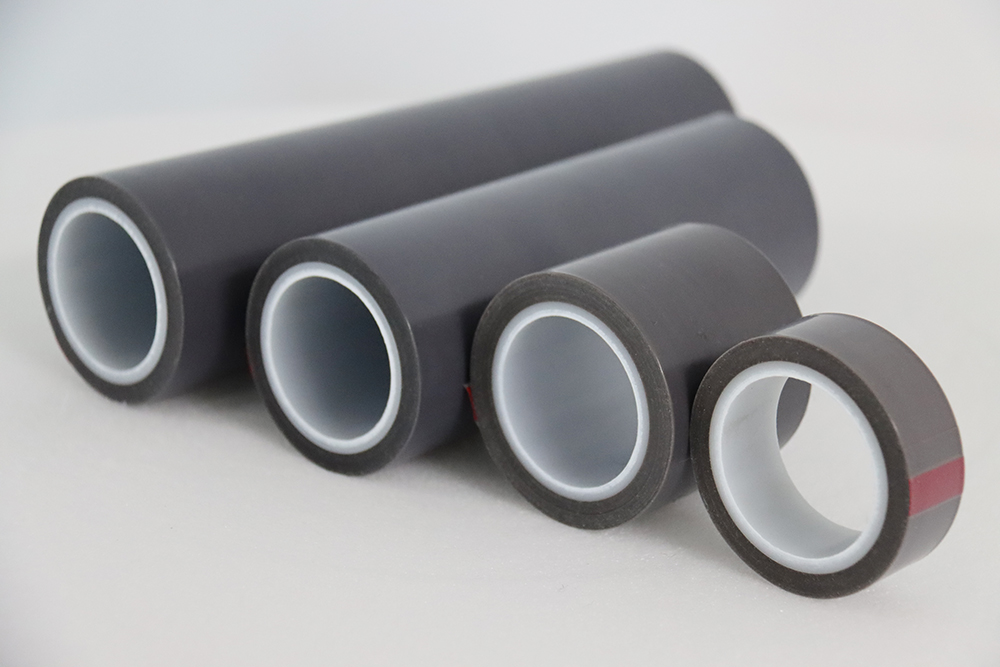

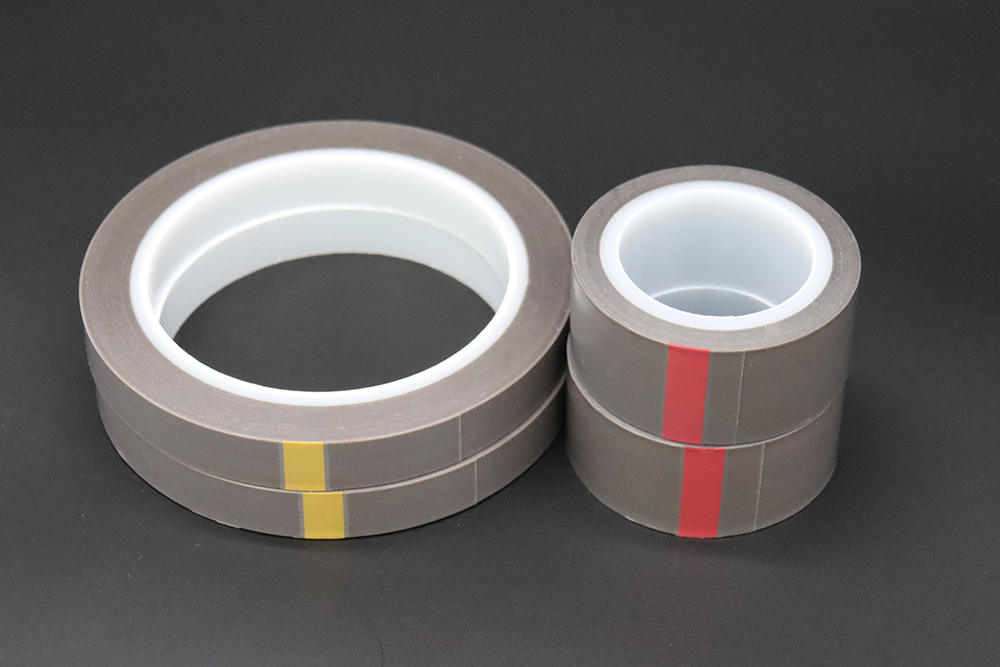

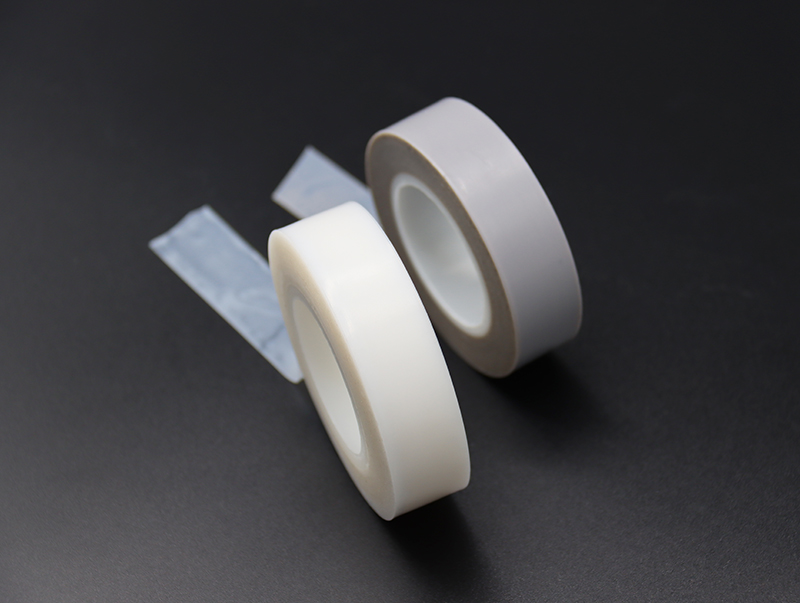

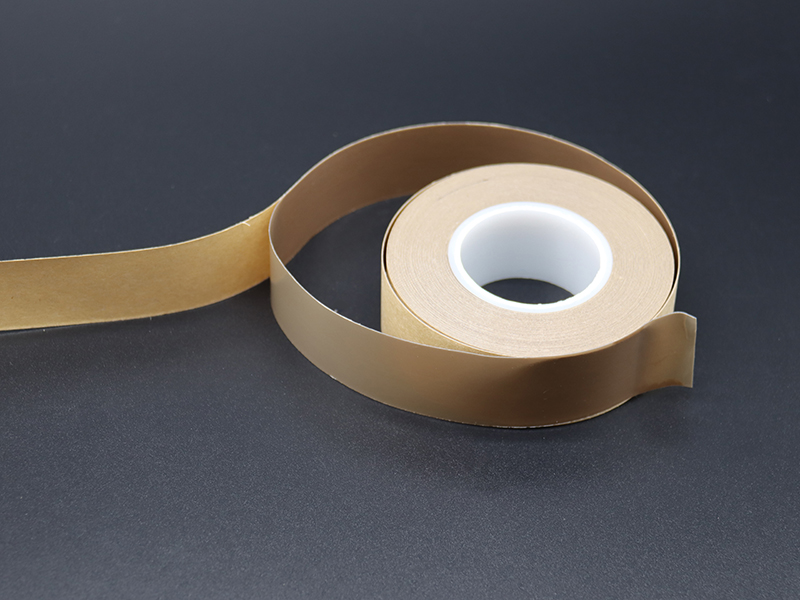

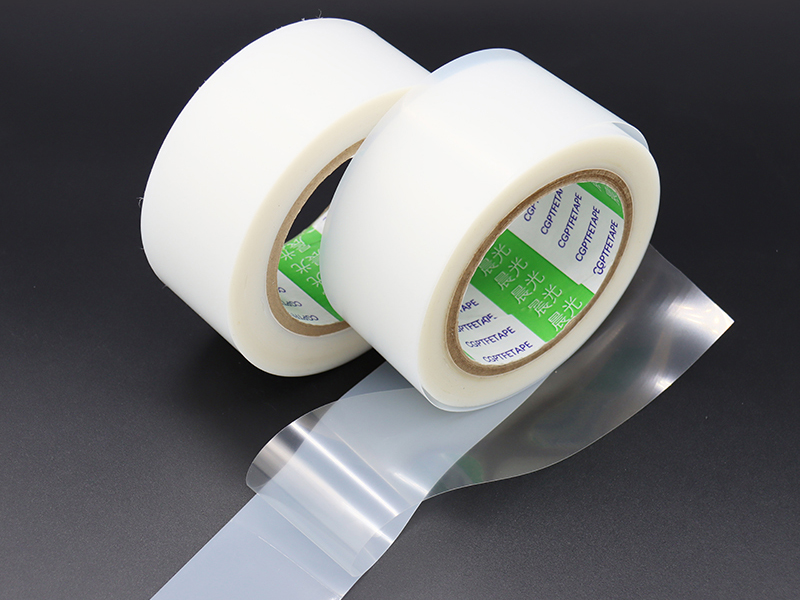

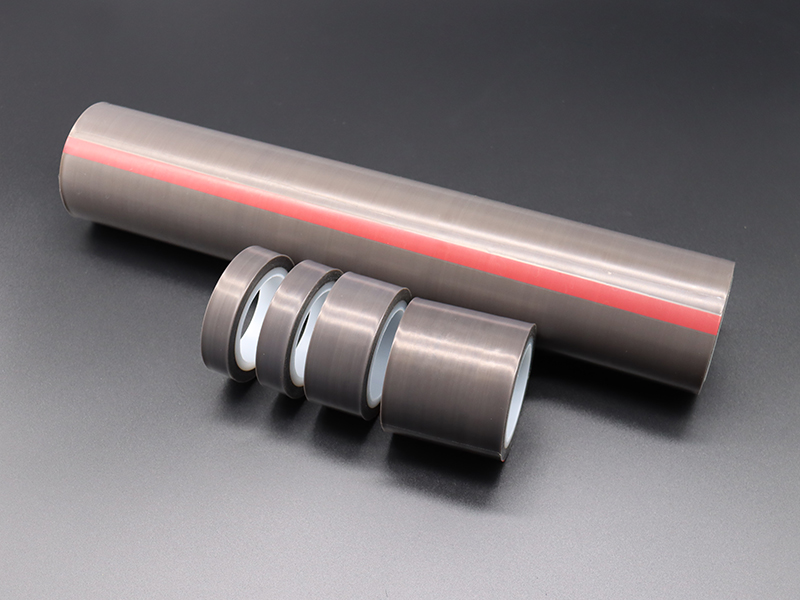

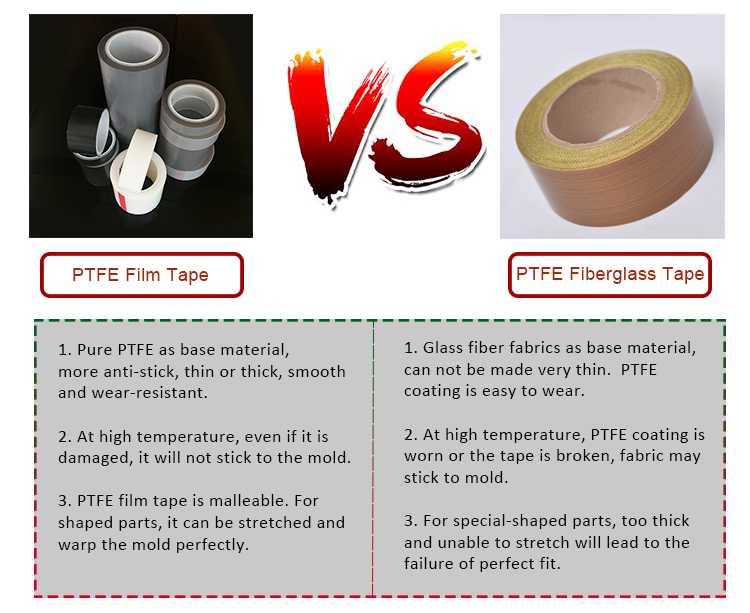

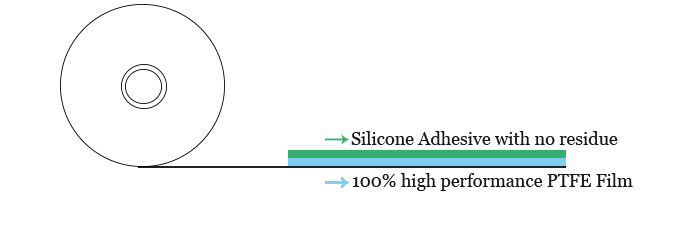

PTFE(Teflon) Film Tape uses high performance polytetrafluoroethylene (PTFE) film made from 100% virgin PTFE resin as base material. This tape offers an extremely low coefficient of friction, in combination with a pressure sensitive silicone adhesive, creates a smooth, non-stick surface over a variety of substrates to assist in the movement of materials in many types of lay-flat applications. PTFE film tapes will release from most resin systems. They are ideal for use on tooling blocks and all areas where high elongation and release is needed. CG PTFE film tapes will form to critical contours and mold surfaces while offering multiple releases or may be used to cover multiple detail mold seams.

- Mobile:+86 13809076956

- Twitter:https://twitter.com/TaizhouLtd

- E-mail: isabelyuan@yahoo.com

Notice:

New upgrade type, please click here: New. Upgrade Gray PTFE Film Silicone Adhesive Tape

Key Characteristics

Non-stick PTFE film provides a slippery and anti-friction surface.

Silicone adhesive provides clean removal with no residue.

Outstanding chemical resistance and inertness

High temperature resistance to 260℃

Dielectric insulation properties

Good wear resistance

Superior flame resistance

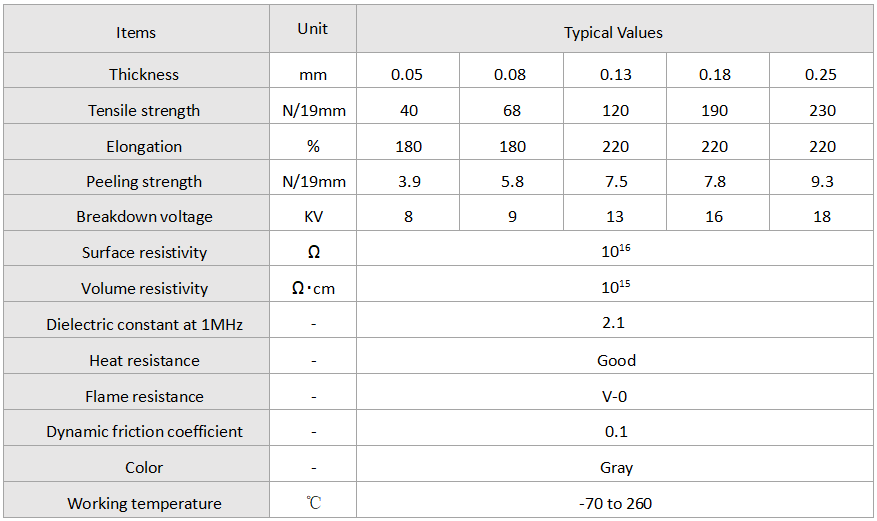

Specifications

Adhesive: Silicone

Backing: PTFE film

Thickness: 0.05mm, 0.08mm, 0.13mm, 0.18mm, 0.25mm (Customized)

Width: Max 500mm

Continuous Working Temperature: -70°C to 260°C

Applications

Providing excellent mold release in composite bonding

Wrapping and insulation connection of high temp. and high voltage cables

Wrapping web rollers to reduce friction

Covering web former edges to minimize friction during folding

Noise reduction of parts where surfaces rub together

Increasing wear life of parts

Provides permanent release and superior surface finish, saving time and improving quality.

Protects rubber tooling mandrels and intensifiers from resin attack, extending tool life and reducing cost.

Good elongation makes application to complex shapes easier, reducing time and improving quality.

Technical Parameters